(866) 986-6860

Give us a Call

Mon - Fri: 8AM-5PM

Sat - Sun: By Appointment

Call for Emergency Services

Give us a Call

Call for Emergency Services

Contact Absolute Water Technologies to request a quote or site survey.

The Marlo ‘MRO-8H’ Series Industrial Reverse Osmosis system is designed for industrial applications requiring high purity water (98-99% salt rejection).

Nominal output capacities of 36,000-432,000 GPD (25-300 GPM).

Flexible design allowing for easy customization to meet tight engineering specifications.

The MARLO MRO-1L Industrial Reverse Osmosis System is a specialized, hybrid design that combines the simple operation and economical features of a traditional 4″ style machine with higher product flow rates and industrial appearance of an 8″ style machine. The use of single membrane element housings significantly reduce the skid footprint making it the perfect industrial RO system for locations with tight available floor-space.

The MARLO MRO-4-LP Series Commercial Reverse Osmosis system offers a low pressure, energy saving design for light commercial water purification applications requiring an economical means for high purity water. Nominal output capacities of 3,600 – 16,200 GPD. These units come standard with a solid-state digital controller and automatic inlet shut-off valve among many other standard and optional features.

Low pressure, energy saving design for light commercial water treatment applications requiring an economical means for high purity water. Nominal output capacities of 3,600 – 16,200 GPD.

The MARLO MRO-4 Series Reverse Osmosis systems are designed for larger commercial reverse osmosis and industrial reverse osmosis applications requiring high purity water (98-99% salt rejection).

The MARLO ‘MRO-2.5’ Series Economy type Commercial Reverse Osmosis system is designed for commercial water treatment applications requiring purified water (90%+ salt rejection). Nominal output capacities of 200-2,500 GPD. Vertically arranged membrane housings allow for minimal floor space requirements. A Deluxe Upgrade Package is available which replaces the brass feed pump with a stainless steel pump.

Economy type RO machines are designed for commercial water purification applications (90%+ salt rejection). Nominal output capacities of 200-2,500 GPD. Vertically arranged membrane housings for minimal floor space requirements.

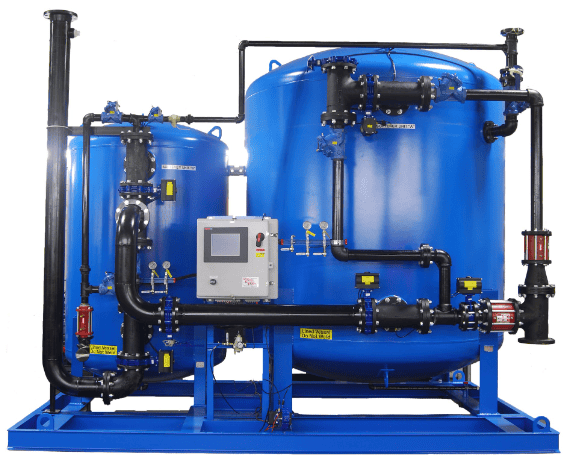

The MARLO ‘MR’ Series is designed for larger commercial and industrial water softening applications. Individual tank capacity ranges from 150,000 grain to 1,050,000 grain with continuous flow rates of 20-190 GPM. Single tank, multi-tank parallel, twin alternating, and triple alternating systems are available with a wide variety of timer and water meter controllers.

The MARLO ‘MRG’ Series is the corrosion resistant alternative to the ‘MR’ Series for industrial or large commercial water softening applications. These softeners are equipped with FRP resin tanks and Sch 80 PVC exterior piping and valves. All ‘MRG’ systems are factory skid mounted, pre-piped, pre-wired. Standard designs available for twin and triple tank configurations.

The MARLO ‘MHC’ Series is designed for large industrial water softening applications. Individual tank capacity ranges from 1,200,000 grain to 5,400,000 grain with continuous flow rates of 100-1,150 GPM. Single tank, multi-tank parallel, twin alternating, and triple alternating systems are available with a wide variety of timer and water meter controllers.

MARLO ‘MST’ commercial water softening systems are designed to fit the requirements of many types of commercial and institutional applications. Whether it is for boiler feed or domestic supply water for a school or hotel, the MST offers a robust and efficient solution for reducing mineral scale, soap usage, and energy consumption in the plumbing and other water using equipment.

The MARLO ‘MAT’ Series is designed for commercial & industrial water softening applications demanding continuous soft water supply. All systems are twin-alternating configurations with one tank in regeneration or stand-by at all times. Individual tank capacity ranges from 15,000 grain to 450,000 grain with continuous flow rates of 1-45 GPM.

The MARLO ‘MGT’ Series is designed for a wide range of commercial and industrial water softening applications. Individual tank capacity ranges from 15,000 grain to 1,200,000 grain with continuous flow rates of 1-215 GPM.

Our Small Volume RO Systems are designed to purify small to medium volumes of water reliably and at an affordable price. All systems are available with complete factory warranty and expert field service.

The Small Volume Series RO systems are just part of the family of water treatment products available. We offer complete system capabilities, including evaluation and design services, state-of-the-art equipment utilizing membrane and ion exchange technology, and expert field service. For more information and system quotation, contact us.

Our LTF2, LTF3, and LTF4 Series RO Systems are designed to purify medium to large volumes of water reliably and at an affordable price. All systems are available with complete factory warranty and expert field service.

The LTF2, LTF3, and LTF4 Series RO systems are just part of the family of water treatment products. We offer complete system capabilities, including evaluation and design services, state-of-the-art equipment utilizing membrane and ion exchange technology, and expert field service. Contact us for more information and system quotation.

Pre-engineered, cataloged systems are available to provide exchange capacities from 1,200,000 to 5,400,000 grains of hardness removal per vessel and service flow rates up to 750 gallons per minute per vessel.

Increased flow rates and greater treatment capacities can be achieved by banking multiple vessels together. Water Softener Systems will also provide increased flow rates, additional capacity and continuous, uninterrupted softened water.

Pre-engineered, cataloged systems are available to provide exchange capacities from 150,000 to 1,050,000 grains of hardness removal per vessel and service flow rates up to 750 gallons per minute per vessel.

Increased flow rates and greater treatment capacities can be achieved by banking multiple vessels together. Water Softener Systems will also provide increased flow rates, additional capacity and continuous, uninterrupted softened water.

Pre-engineered, cataloged systems are available to provide exchange capacities from 150,000 to 1,100,000 grains of hardness removal per vessel and service flow rates up to 750 gallons per minute per vessel.

Increased flow rates and greater treatment capacities can be achieved by banking multiple vessels together. Water Softener Systems will also provide increased flow rates, additional capacity and continuous, uninterrupted softened water.

Pre-engineered, cataloged systems are available to provide exchange capacities from 15,000 to 3,000,000 grains of hardness removal per vessel and service flow rates up to 750 gallons per minute per vessel.

Increased flow rates and greater treatment capacities can be achieved by banking multiple vessels together. Water Softener Systems will also provide increased flow rates, additional capacity and continuous, uninterrupted softened water.

Service Center Locations:

Phone Number: (866) 986-6860

Email: info@absolutewatertech.com

Hours:

*Emergency service is available.

Absolute Water Technologies

(866) 986-6860

info@absolutewatertech.com

Absolute Water Technologies understands that your privacy is extremely important to you. We understand, it is just as much a concern for us.

Absolute Water Technologies is in the business of selling high-quality equipment for your water purification needs. Not your personal or business information.

Whenever you purchase from our online store, any and all credit card transactions are handled through our gateway processors. We currently offer PayPal for our customers who want to use their PayPal account or credit card. In addition, we also offer straight credit card processing through Authorize.net. In both cases, the respective Privacy Policies for each solution is available at the following websites. Please be certain to review this information before ordering through our online store.

Absolute Water Technologies does not store any financial information of any of our customers on this site or domain.

© All rights reserved Sitemap Privacy Policy Terms of Use