Avoiding Design Pitfalls of a High Purity Water Treatment System

Avoiding Design Pitfalls of a High Purity Water Treatment System

First Step:

Most critical to PROPERLY designing a high purity water treatment application is

It is critical to identify the true quality needs to make sure a system is not under designed or over designed. Overdesigning a system may not seem like a large concern, but unnecessary system components can have an unwarranted operating expense impact.

The following are well know agencies and organizations that have well published standards that can be helpful in system design. Understanding the requirements and how to get there is paramount.

- College of American Pathologists (CAP) http://www.cap.org/web/home

- Clinical and Laboratory Standards Institute(CLSI) http://clsi.org/

- American Society for Testing and Materials (ASTM)http://www.astm.org

- United States Pharmacopoeia (USP) establishes specifications for USP purified water and USP water for injection (WFI) http://www.usp.org

- The ASTM and Semiconductor Equipment and Materials International (SEMI) have established specifications for electronics grade water used to manufacture microelectronic devices. http://www.semi.org/en/Standards

- The Association for the Advancement of Medical Instrumentation (AAMI) has established water quality standards for water used in hemodialysis applications. http://www.aami.org/

Second Step

Sizing and Storage

Very critical to a system is sizing and storage. In general, most systems are oversized due to not understanding the instantaneous demand of a system. Oversizing a system can lead to an array of problems including bacteria and endotoxin contamination. Systems that provide water on a seasonal basis can be extra tricky and take a skilled water system design professional to navigate. Often pickling or other means of preparing a system for storage is impractical so other design mechanisms must be employed to avoid contamination during slower periods.

Recirculating water is always the best action, when at all possible through a decontamination device such as a UV light followed by final/post filtration. Recirculating water disrupts the establishment of biofilms which are breeding grounds for compounded bacterial growth. Water degrades as stored over time. If a polishing unit is used on a loop, continually passing it through the polisher helps keep final water quality at or above standards on larger central systems.

Third Step:

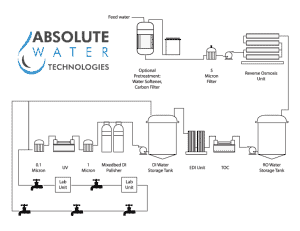

Understanding major system components and what they do will ensure proper placement.

Placement of key components can be critical. For example, UV lights are of two forms, 185NM and 254 NM. It is important to understand that the 185 NM light is for TOC destruction and the 254NM is used for bacterial control. If deionization polishers are used on a system it is critical to understand proper placement of each unit. Peppering in a few components but not applying them correctly can do a system more harm than good.

Pre-treatment-

Proper sizing of a carbon filtration, multi-media or a water softener has an impact on the efficiency and effectiveness of your system. Many agencies such as AAMI have minimum EBCT- Empty Bed Contact Times for carbon filters to remove chlorine/chloramines and minimum removal capacities for hardness in regard to water softeners.

Sizing is a large consideration but also important is deciding if you need a single pass or double pass system for the feed water ranges you have and the final quality you need. Additionally, will you need a chemical sanitizable system or a heat sanitizable system?

Deionization Polishers SDI- Portable Exchange Tanks:

Selecting a reputable company that rinses the deionization tanks (SDI) to ensure quality and remove any potential bacteria is key. Does your supplier use the proper regeneration methods and high-grade resin? Not all service deionization tanks (SDI) are the same. Sizing is important to understand flow characteristics and removal capacities.

CDI/EDI Systems-

Understanding how a Continuous Deionization (CDI) system or Electro Deionization System (EDI) works and when it is economically favorable to a system is important to understand.

Final Filtration-

Properly sizing the final filtration is important. Both flow rates and micron size are critical. Oversizing a filter can lead to endotoxin or bacteria concerns and under-sizing can cause flow restrictions or impact removal effectiveness.

UV-

Sizing and the type of nanometer frequency are considerations that must be studied. Heat in a system due to oversizing can actually promote bacterial growth.

Storage Tank-

A conical or cone bottom designed tank costs more initially but is critical in a high purity system to help prevent bacterial growth. Spray balls/or bars on the return line to keep the entire tank wet and a properly designed tank including applicable overflow filtration is important.

Point of Use Systems-

Would and Elga or Millipore polishing system be a good application for the area you are looking at? What are the differences in the system? What system do you need for Type 1, 2, or 3 water and what is the best overall unit for the application. Can one unit serve two different applications?

Fourth Step:

Installation:

Proper piping material is important such as avoiding products that can leach off harmful chemicals into the product water. Knowing the proper operating pressures, temperatures, and final water quality resistivity design parameters are vital. Installation of a high purity water system should avoid dead legs. Dead legs should be minimal and at a maximum 5 times the pipe diameter. When turns are needed 45 degree joints should be used in conjunction rather than 90degree turns. Pipe joints need to be clean and ridges avoided as much as possible. The smoother the piping material and the reduced number of joints are favorable. Proper system return velocity is a factor in combating bacteria and should be at a minimum 3ft/sec.

For help in designing a High Purity Water system or learning more about our water system services for a current High Purity Water System please contact us at info@absolutewatertechnologies.com or call us 1-866-986-6860.