9 QUESTIONS YOU SHOULD ASK BEFORE PURCHASING A NEW WATER PURIFICATION SYSTEM

Many different laboratories require a consistent supply of high purity water. From those that need it for analytical experiments through to those that use it for cell culturing, with so many different ways of using water, it’s important to ensure that your purification system meets your laboratory’s individual needs.

So, before purchasing a new water purification system, have you considered all the factors that will affect how your set-up will be used? Here are nine questions every laboratory should ask before purchasing a water purification system.

1. What type of water do I need for my application?

Different laboratory techniques require different levels of water purity. Some applications are more sensitive to contamination and may require a higher grade of water quality. For example, water for cleaning laboratory glassware doesn’t typically need to be that pure, whereas even low levels of contamination can interfere with mass spectrometry or HPLC experiments. Money and other resources can be saved by only using higher purity water for those applications that need it.

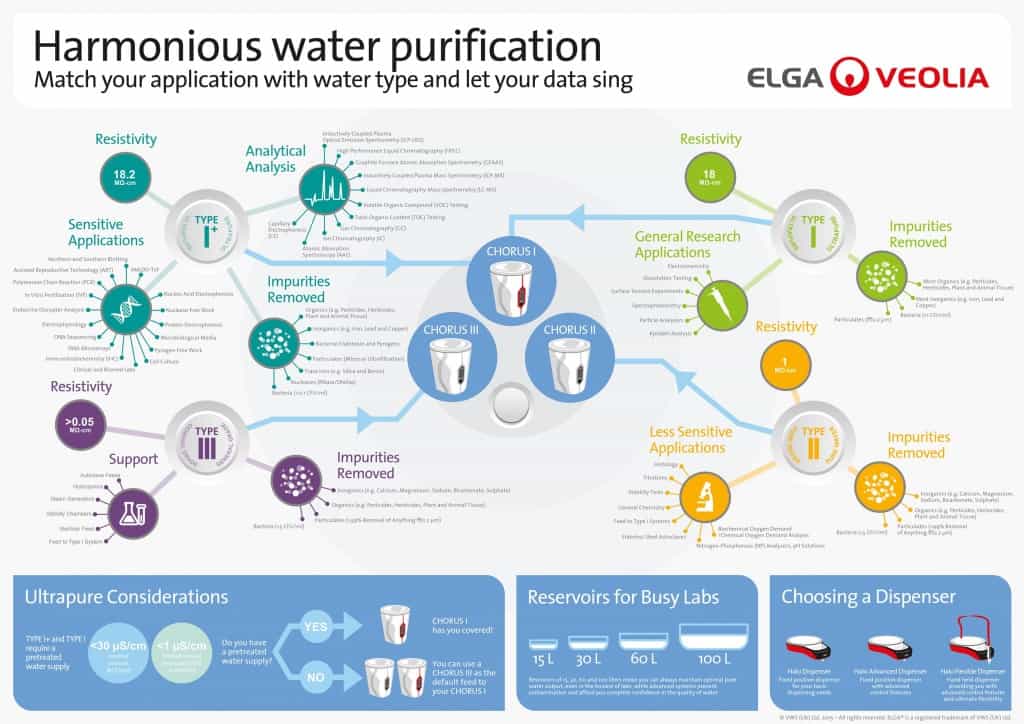

It is therefore important to ensure the water purity you use is suitable for your application. Water purity ranges from Type I+, which has a resistivity of 18.2 MΩ and is used in highly sensitive experiments, to Type III, which has a resistivity of >0.05 MΩ and is used as feedwater for purification systems and for washing machines and autoclaves.

You can use our useful infographic to help match the type of water you’ll need to the applications you use.

2. What impurities do I need to remove?

A typical glass of unpurified water contains bacteria, organic material, ions and gases, amongst other contaminants. Water purification systems use a combination of purification methods, such as reverse osmosis, ion-exchange, electrodeionization, ultraviolet light, irradiation and ultrafiltration to remove these impurities. Some systems not only purify water, but also monitor the levels of these contaminants via in-line resistivity and TOC measurements to ensure optimal water quality.

Different laboratory applications are affected by different types of impurities. For example, unwanted bacteria can introduce foreign DNA into a sequencing project, while organic contaminants may produce unwanted background readings in MS experiments. It’s therefore essential to ensure your water purification system supplies water of a grade that meets your requirements.

3. Do I need more than one type of water?

The grade of water quality your laboratory will need depends on the type of techniques you use. If you use multiple techniques that require a range of water purities, you should consider a system that offers a range of supply options. Some systems allow mains water to be pretreated to Type III level, and further purified to ultrapure Type I+ standard, offering varying grades of purity. If you think your use of a particular level of water purity will vary over time, a modular system that can be easily reconfigured could help you easily adapt to meet future demands.

4. What is my daily water usage?

A typical laboratory is estimated to use around five-times more water than a comparably sized office block – that’s approximately 35 million litres per year. Whether you use more or less than this amount, it is important to ensure a consistent supply. A purification system enables a consistent flow of high quality water, eliminating the disruption encountered when bottled water runs out.

It’s also important to consider whether your laboratory experiences particularly high water usage periods. Water purification systems can be built with reservoirs that come in various sizes, which help to mitigate problems associated with high demand. The PURELAB Chorus system, for instance, offers reservoir storage of up to 100 litres, ensuring optimal pure water output even in the busiest of labs. Such modular systems mean that reservoir capacity can be expanded easily, should you find your water demands increase.

5. Do I need water in adjoining labs?

It’s also important to consider whether additional labs will need their own access to a high quality water supply. Will their applications be different, and therefore require a different grade of water? Perhaps you’re even looking to install a water purification system for the whole building.

Fortunately, a range of supply options exist, from centralized systems to mains water purified at the point-of-use. Multi-step systems can use a locally pretreated supply that is purified further prior to use. Reservoirs can also be used to supply multiple laboratories with a consistently pure water supply.

6. What is my feedwater like? Has it been tested?

The water purification system you’ll need depends not only on your purity demands, but also on the level of contamination in your feedwater. Some suppliers will check this for you and can offer personal advice on how to match your system to your unique needs.

For applications that require lower grades of water purity, such as Type II and Type III, water purification modules may not require additional feedwater purification. However, for techniques that require a supply of ultrapure Type I or Type I+ water, your feed supply will require pretreatment. The modular nature of the Chorus system means that the CHORUS III purification unit can be used to provide feedwater into downstream, ultra-high purification modules such as the CHORUS I.

7. Can I recycle my old unit?

Existing built-in water purification systems can be large and may involve pipework and infrastructure that is expensive or difficult to remove. One of the benefits of a modular system is that individual units can be easily upgraded and new capabilities installed, without the need to replace the whole system. Such systems can therefore offer benefits in terms of cost and can minimise disruption caused during maintenance.

8. I have equipment that requires water. What type of water do I need?

Type III water is suitable for use for support applications such as autoclaves, steam generators and hydroponics. It’s still important to use a water purification system, which remove dissolved ions and small organics, to ensure these systems remain in good working condition.

On the other hand, analytical instrumentation such as HPLC and other chromatographic methods require ultra-pure Type I+ water. Using poor quality water can introduce particulates into the system which can cause a noisy baseline in measurements. The build-up of particulates can also lead to an increase in back-pressure and cause columns to explode and damage the HPLC pump and injector. For more troubleshooting tips to get the best results from your liquid chromatography experiments, download our tricks and solutions guide [link to troubleshooting whitepaper, http://www.elgalabwater.com/en-gb/wp4-troubleshooting-water-problems].

9. How much space do I have to fit a product?

Even the busiest of labs have more space than you might think! Modular water purification systems push the boundaries of storage confinement and offer flexible options for location. The PURELAB Chorus system, for instance, can sit under a bench, while other system components can be wall-mounted, stacked or even physically separated and connected together to make the best use of nooks and crannies around the lab. Likewise, water storage reservoirs can often be located in unfrequented laboratory spaces.

Build a system tailored to your needs

Absolute Water Technologies is an official representative of Veolia / Elga. Please contact us with any lab water treatment needs.